Cermet Chunk

Statistics

Horizon Changes

Other Uses

| Guild Points Value: None |

| Used in Quests: |

| Resale Price: 500~512 gil |

| Guild Resale Price: ~750 gil |

Synthesis Recipes

- Yield: Cermet Chunk x 1

HQ 1: Cermet Chunk x 2

HQ 2: Cermet Chunk x 3

HQ 3: Cermet Chunk x 4 - Fire Crystal

- 4 x Magic Pot Shard

HQ 1: Cermet Chunk x 2

HQ 2: Cermet Chunk x 3

HQ 3: Cermet Chunk x 4

- 2 x Golem Shard

HQ 1: Cermet Chunk x 2

HQ 2: Cermet Chunk x 3

HQ 3: Cermet Chunk x 4

- 2 x Doll Shard

Used in Recipes

59

59  09

09  48 Leucous Voulge

48 Leucous Voulge

62 Cermet Knife

62 Cermet Knife

63

63  16 Cermet Claws

16 Cermet Claws

65

65  08 Ice Arrow

08 Ice Arrow

66

66  06 Battery

06 Battery

66

66  39 Hanger

39 Hanger

68 Cermet Sword

68 Cermet Sword

70 Saber

70 Saber

73

73  45 Cutlass

45 Cutlass

75 Cermet Kukri

75 Cermet Kukri

76

76  18 Kilo Battery

18 Kilo Battery

76 Halcyon Rod

76 Halcyon Rod

78

78  29 Jamadhars

29 Jamadhars

86

86  31

31  16 Mega Battery

16 Mega Battery

90 Espadon

90 Espadon

64

64  40

40  57 Hosodachi

57 Hosodachi

71

71  51 Gold Cuisses

51 Gold Cuisses

72

72  54 Gold Armet

54 Gold Armet

74

74  54 Gold Sabatons

54 Gold Sabatons

77

77  54 Gold Gauntlets

54 Gold Gauntlets

78

78  ?? Gold Cuirass

?? Gold Cuirass

93

93  ?? Cursed Diechlings

?? Cursed Diechlings

94

94  ?? Cursed Schuhs

?? Cursed Schuhs

96

96  ?? Cursed Handschuhs

?? Cursed Handschuhs

97

97  ??

??  ?? Cursed Schaller

?? Cursed Schaller

98

98  ?? Cursed Cuirass

?? Cursed Cuirass

63

63  51

51  ?? Sakurafubuki

?? Sakurafubuki

71

71  56

56  ?? Schwert

?? Schwert

86

86  57 Cermet Lance

57 Cermet Lance

Obtained from Desynthesis

90 Espadon

90 Espadon

71 Gold Cuisses

71 Gold Cuisses

93 Ice Lance

93 Ice Lance

How to Obtain

Auction House Category: Materials > Alchemy ![]()

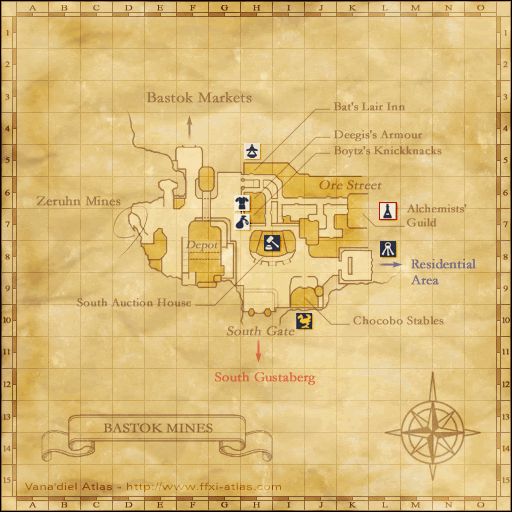

Merchants

| Price: 19,520 gil | ||

|---|---|---|

| Name | Location | Type |

| Maymunah | Bastok Mines (K-7) | Alchemists' Guild (Bastok)

|

| Odoba | Bastok Mines (K-6) | |

- not available unless a player previously sold the item to the npc.

Quests

- Strange Apparatus The Cermet Chunk is one possible reward for completing this mini-quest.

Historical Background

A cermet is a composite material composed of ceramic (cer) and metallic (met) materials. A cermet is ideally designed to have the optimal properties of both a ceramic, such as high temperature resistance and hardness, and those of a metal, such as the ability to undergo plastic deformation. The metal is used as a binder for an oxide, boride, carbide, or alumina. Generally, the metallic elements used are nickel, molybdenum, and cobalt.

Depending on the physical structure of the material, cermets can also be metal matrix composites, but cermets are usually less than 20% metal by volume. Cermets are used in the manufacture of resistors (especially potentiometers), capacitors, and other electronic components which may experience high temperatures. In the tool world, tungsten carbide is considered a cermet although tungsten carbide is so widely used that it is considered a class by itself. Cermets are being used instead of tungsten carbide in saws and other brazed tools due to their superior wear and corrosion properties. TiCN, TiC, TiN and similar can be brazed like tungsten carbide if properly prepared however they require special handling during grinding. More complex materials, known as Cermet 2 or Cermet II, are being utilized since they give considerably longer life in cutting tools while both brazing and grinding like tungsten carbide. Some types of cermets are also being considered for use as spacecraft shielding as they resist the high velocity impacts of micrometeoroids and orbital debris much more effectively than more traditional spacecraft materials such as aluminum and other metals.

After World War II, the need to develop high temperature and high stress-resistant materials in the US became clear. During the war, German scientists developed oxide base cermets as substitutes for alloys. They saw a use for this for the high-temperature sections of new jet engines as well as high temperature turbine blades.

Today ceramics are routinely implemented in the combuster part of jet engines because it provides a heat resistant chamber. Ceramic turbine blades have also been developed. These blades are lighter than steel and allow for greater acceleration of the blade assemblies. The United States Air Force saw potential in the material technology and became one of the principal sponsors for various research programs in the US. Some of the first universities to research were Ohio State University, University of Illinois, and Rutgers University. The word cermet was actually coined by the United States Air Force, the idea being that they are a combination of two materials, a metal and a ceramic. Basic physical properties of metals include ductility, high strength, and high thermal conductivity. Ceramics possess basic physical properties such as a high melting point, chemical stability, and especially oxidation resistance.

The first ceramic metal material developed used magnesium oxide (MgO), Beryllium oxide (BeO), and aluminum oxide (Al2O3) for the ceramic part. Emphasis on high stress rupture strengths was around 980C.[2] Ohio State University was the first to develop Al2O3 based cermets with high stress rupture strengths around 1200C. Kennametal, a metal-working and tool company based in Latrobe, PA, developed the first titanium carbide cermet with a 2800 psi and 100 hour stress-to-rupture strength at 980C. Jet engines operate at this temperature and further research was invested on using these materials for components.

Quality control in manufacturing these ceramic metal composites was hard to standardize. Production had to be kept to small batches and within these batches, the properties varied greatly. Failure of the material was usually a result of undetected flaws usually nucleated during processing. The existing technology in the 1950s reached a limit for jet engines where little more could be improved. Subsequently, engine manufactures were reluctant to develop ceramic metal engines. Interest was renewed in the 1960s when silicon nitride and silicon carbide were looked at more closely. Both materials possessed better thermal shock resistance, high strength, and moderate thermal conductivity.